Rethinking the Infrastructure Industry Governance.

The potential of $trillions annually added value to world economies and a cleaner, safer, and more secure world.

Neculai C Tutos, Ph.D., Klaro Consulting Principal

The antiquated governance of the world’s largest industry results in inadmissible environmental damage, elevated national security risk, and tolerance of inadmissible high costs for poor-quality national infrastructure.

Abstract

Infrastructure is the industry that builds, operates, and maintains the foundation of our planet’s civilized and prosperous life. Infrastructure is the world’s largest industry; it includes national, regional, and city infrastructures, industrial and service facilities, housing, and monumental structures with national and local significance.

Departing from the antiquated governance of this industry is a national security and environmental imperative and the way to end $trillions annually of lost value to world economies. Resistance to change, the main obstacle to rethinking the infrastructure industry, cannot stay in the way of today’s national security and environmental imperatives.

The antiquated infrastructure industry governance is an inadmissible cost for the world’s taxpayers and consumers of goods and services. Governments, the largest investors in infrastructure facilities, must lead the transformation of the infrastructure industry; they have the highest level of responsibility for the security and performance of the nation’s mission-critical facilities.

The 21st-century infrastructures are, to a growing extent, digitally controlled infrastructures; the integration of two digital technologies, the Internet of Things (IoT) and the Product Digital Twin (PDT), add immense capabilities to addressing the national security, environmental, and business profitability objectives. The antiquated infrastructure governance keeps the infrastructure industry decades behind the whole economy in business digitization.

Acknowledgments

Sir John Egan and John Voeller contributed challenging reviews and valuable recommendations to the development of this paper.

Sir John Egan is known for unparalleled success in dealing with challenging business transformation projects in manufacturing as the CEO of Jaguar and in the construction of airports as the CEO of the British Authority of Airports. Sir John Egan chaired the Rethinking Construction task force commissioned by the British Government. Later, he was President of the Confederation of British Industry and the British Institute of Management. Sir John Egan and Dr. Tutos are the coauthors of the “Digital-age construction-manufacturing Convergence” section of “The Digital Twin” book, Springer 2023. Ninety experts worldwide contributed to summarize four decades of digital advances and successes and to define the Digital Twin’s potential for the decades ahead.

John Voeller worked at the Executive Office of the President as a senior analyst on homeland security and as a consultant for the Department of Homeland Security on all aspects of infrastructure protection. John Voeller is a former Senior Vice President, Chief Knowledge Officer, and Chief Technology Officer at Black and Veatch, the largest privately held engineering company in the United States. John Voeller also served as chairman of ASME’s Critical Asset Protection Initiative, leading eight teams of world experts in developing the industry’s agenda for homeland security needs and planning first responder actions and risk analysis of terrorist and catastrophic incidents.

A. Infrastructure is the industry that builds, operates, and maintains the foundation of a civilized and prosperous life.

Infrastructure is the industry that builds, operates, and maintains national, regional, and city infrastructures, industrial and service facilities, and housing. Infrastructure is the largest industry that produces complex products for years or decades of use; some of the infrastructure products, such as bridges, tunnels, and buildings, are created for centuries of use.

“Building to withstand nature’s mighty powers-storms, floods, earthquakes, and gravity-engineers serve us well. Engineering evolved over 5,000 years, from piled stones to steel skyscrapers, from primitive rope bridges to the immense spans serving cities worldwide……..Engineering is essentially a social art, increasing in importance as life becomes more complex. We depend on it as we do on nature itself, for it makes nature more tractable an accessible.” William L. MacDonald, Building Historian, in the foreword to “The Builders, Marvels of Engineering”, National Geographic Society.

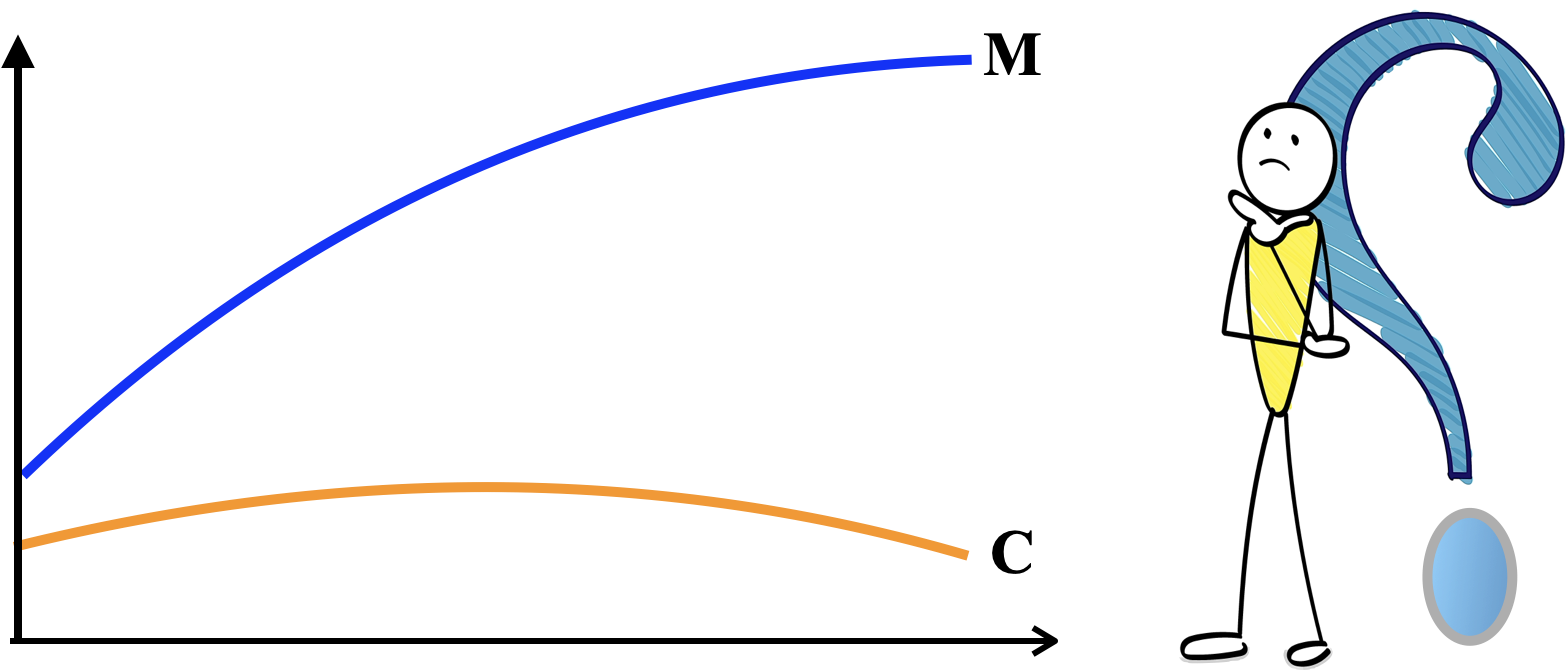

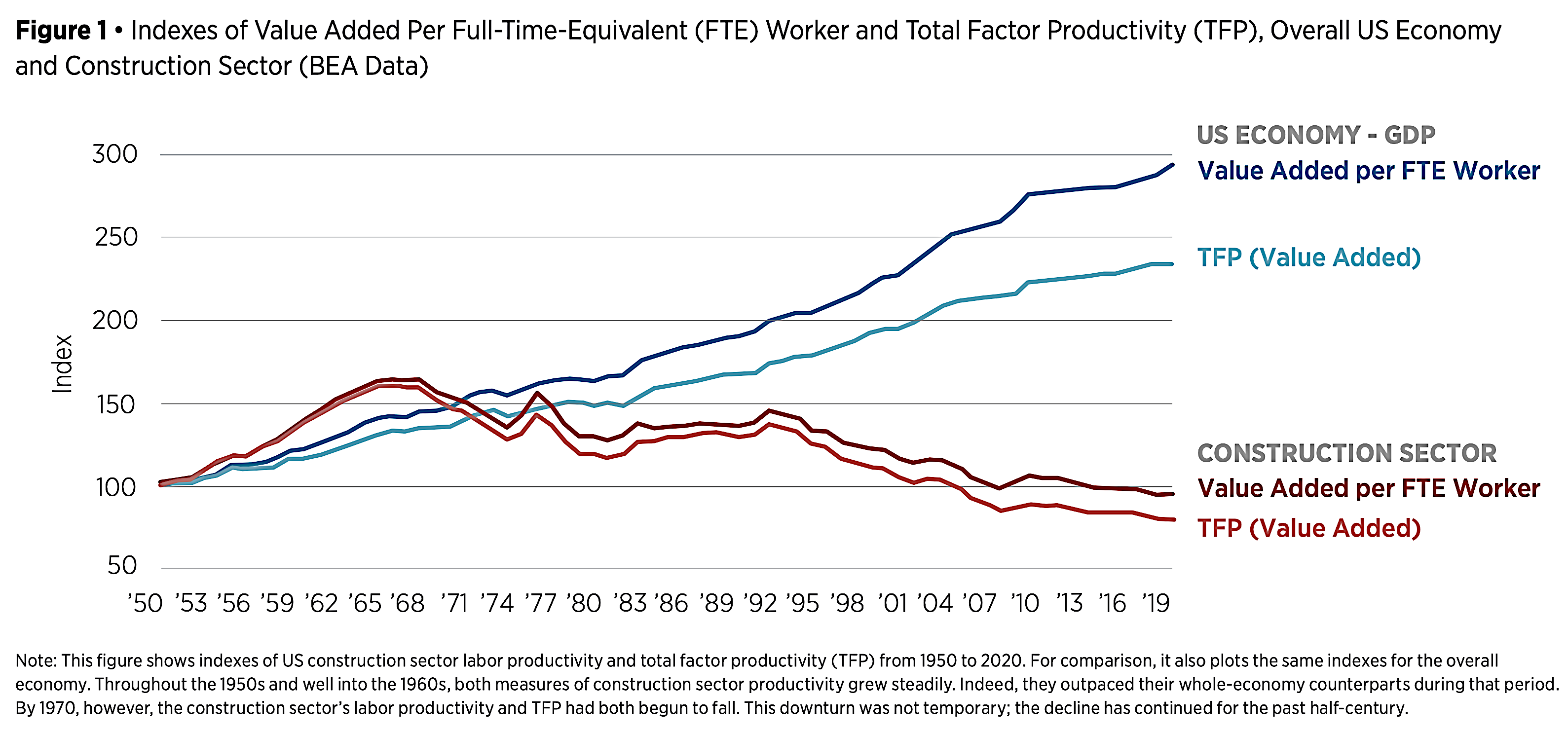

On average, the whole U.S. economy benefited from about 260% higher productivity, while construction productivity in 2020 was about 40% lower than the 1970 level. During the same period, labor productivity in manufacturing grew nine-fold.

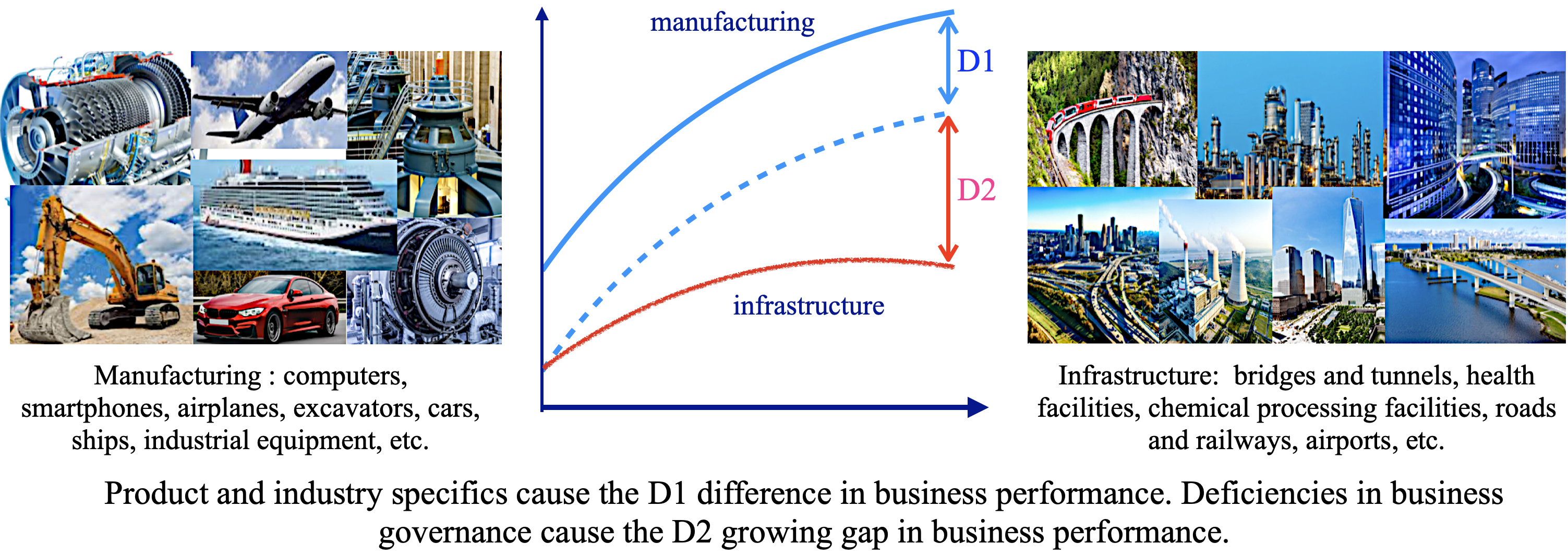

B. Infrastructure is the only industry facing decades of growing business performance gap relative to all the other industrial sectors

Inadmissible delays and cost overruns in the delivery of construction projects translate into $trillions annually of lost value in world economies, in lower quality of the national infrastructures, and higher vulnerability.

“If construction productivity were to catch up with the entire economy, the industry’s value-added could rise by $1.6 trillion annually” McKinsey Global Institute. (2017). Reinventing construction: A route to higher productivity.

Being the only industry that faces decades of growing gap in business performance relative to all the others and to the total economy in average, indicates clear differences un business governance that cause this troubling condition. Product and industry specifics can cause differences in business performance but not performance decrease. Only deficiencies in business governance can explain decreasing performance in business.

A recent study, “The Strange and Awful Path of Productivity in the U.S. Construction Sector” Austan Goolsbee and Chad Syverson, University of Chicago, Booth School of Business and NBER, January 2023, proves that on average, the whole U.S. economy benefited from about 260% higher productivity, while construction productivity in 2020 was about 40% lower than the 1970 level. During the same period, labor productivity in manufacturing grew nine-fold. The same study indicates that the decreasing construction productivity is not limited to the USA.

“The Strange and Awful Path of Productivity in the U.S. Construction Sector” study is, arguably, the best investigation of the construction productivity trend; the study missed investigating it in the context of the infrastructure industry governing system that causes the trend.

C. There are only two significant differences in business governance that explain and cause the infrastructure industry’s troubling condition.

All industries that make complex physical products, except infrastructure, practice a business governing system to produce competitive use value for years or decades of product lifetime. Infrastructure is the only industry that replaces the product use value objective with the minimum-construction-cost objective and the only one that outsources the governing role in product design and manufacturing/construction.

In all the other industries, the original equipment manufacturer (OEM) organization is responsible for producing competitive product use value and governing the whole process of product lifecycle engineering and product manufacturing. No OEM-like governance exists in the infrastructure industry; by outsourcing the OEM-like responsibility, investors in infrastructure facilities developed a hostile contractual environment under the assumption that this is the way to reduce project risk and cost. It does not work; it causes higher project risk and expense.

In summary, to end its troubled condition, the infrastructure industry will have to eliminate two significant deficiencies in business governance

- The current “minimum construction cost” objective will have to be replaced with the “use value” objective for decades of the facility’s lifetime. The cost of making a new product is an investment for product use value and decades of profitability in business.

- Investors in construction projects will have to assume an OEM-like role in governing the whole facility lifecycle, including construction.

To end the $trillions annually lost value to world economies in the delivery of construction projects, investors in construction projects will have to assume the governing role along the whole facility lifecycle, including the facility design and construction process.

The current hostile contractual environment proved a bad governing concept. The “minimum construction cost” objective proved a bad choice in governing the facility lifecycle.

“Too many clients are undiscriminating and still equate price with cost, selecting designers and constructors almost exclusively on the basis of tendered price. This tendency is widely seen as one of the greatest barriers to improvement.”Rethinking Construction”, the Egan report commissioned by the UK Government.

Investors in construction projects must assume the governing role in construction project governance, adopt the “product use value” objective, and depart from the antiquated hostile contractual environment.

To end the $trillions annually lost value to world economies in the delivery of construction projects, investors in construction projects will have to assume the governing role along the whole facility lifecycle, including the facility design and construction process. The current hostile contractual environment proved a bad governing concept. The “minimum construction cost” objective proved a bad choice in governing the facility lifecycle.

“Rewire the contractual framework. There is a need to move away from the hostile contracting environment that characterizes many construction projects to a system focused on collaboration and problem solving. To achieve this, tendering processes can be based on best value and past performance rather than cost alone, and public processes streamlined. Establishing a “single source of truth” on projects for monitoring progress early, potentially supported by collaborative technology, helps to minimize misalignments and enable joint corrective action.” Page 8 of the “Reinventing Construction: A Route to Higher Productivity”, February 2017 study, McKinsey Global Institute, McKinsey & Company

The deficiency of winning construction projects based on

commitment to lowest construction costs.The ”Rethinking Construction” commissioned by the UK Government was the first to point to the deficiency of winning construction projects based oncommitment to lowest construction costs.

“Too many clients are undiscriminating and still equate price with cost, selecting designers and constructors almost exclusively on the basis of tendered price. This tendency is widely seen as one of the greatest barriers to improvement. The public sector, because of its need to interpret accountability in a rather narrow sense, is often viewed as a major culprit in this respect. The industry needs to educate and help its clients to differentiate between best value and lowest price.” Page 7of the “Rethinking Construction” report. Sir John Egan, the Chairman and CEO of the British Airports Authority (BAA), the world’s largest organization of airports at that time, chaired the Rethinking Construction task force that included top-level executives from the construction industry, steel industry, manufacturing, retail, and banking.

D. Unavoidable questions

Addressing a decades-old business case poses two unavoidable questions:

- HOW has the infrastructure industry survived decades of inadmissible losses? No business can survive decades of low performance.

- WHAT justifies confidence that the infrastructure industry transformation is possible?Transforming a gigantic industry looks to be an impossible mission.

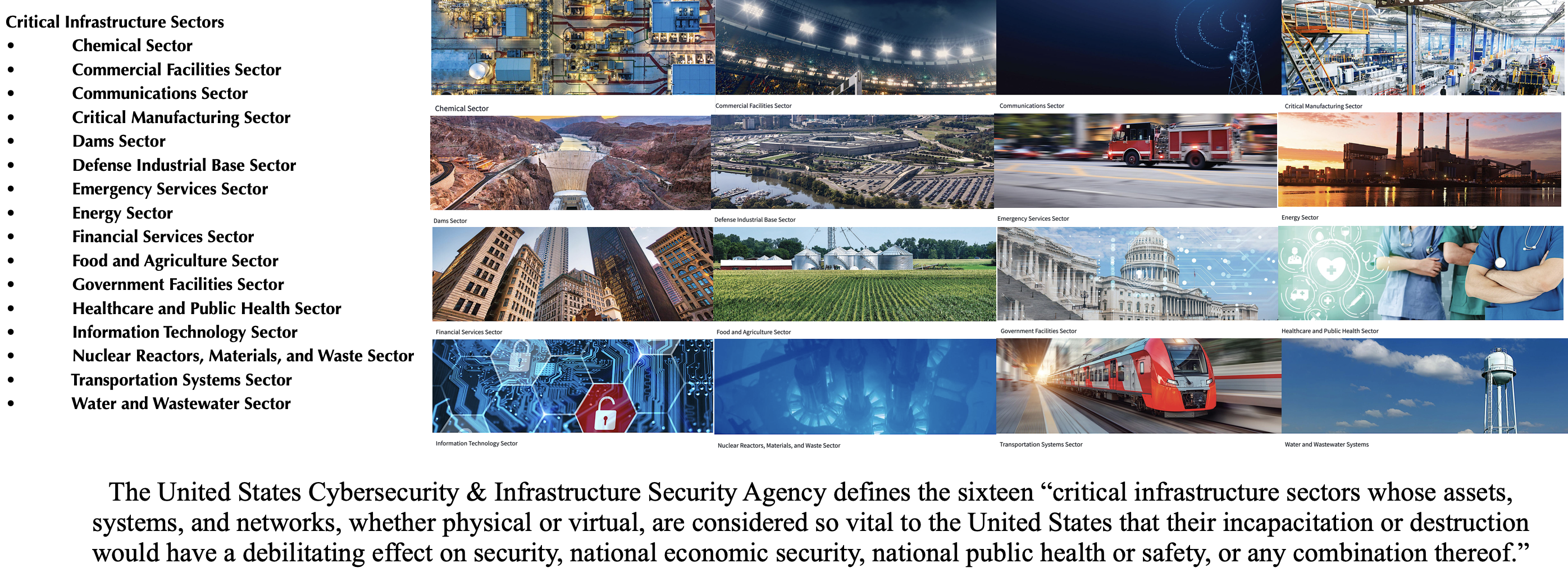

The United States Cybersecurity & Infrastructure Security Agency defines the sixteen “critical infrastructure sectors whose assets, systems, and networks, whether physical or virtual, are considered so vital to the United States that their incapacitation or destruction would have a debilitating effect on security, national economic security, national public health or safety, or any combination thereof.”

E. The troubled infrastructure industry is not an internal affair.

- National security is not an infrastructure industry internal affair; the national infrastructure and all mission-critical infrastructure facilities are increasingly targets of cyber-attacks.

- The high risk of environmental, safety, and security hazards in the operations and maintenance of infrastructure facilities is not an internal affair of the infrastructure industry

Today, most mission-critical facilities are digitally smart, and this is a double-edged sword; it improves facility performance in operations and early detection of equipment and structure pre-failure conditions but elevates the vulnerability to cyber-attacks.

The infrastructure industry has to address the national security imperative. The United States Cybersecurity & Infrastructure Security Agency defines the sixteen “critical infrastructure sectors whose assets, systems, and networks, whether physical or virtual, are considered so vital to the United States that their incapacitation or destruction would have a debilitating effect on security, national economic security, national public health or safety, or any combination thereof.”

All mission-critical facilities must meet the 21st-century national security standards and the requirements for environmental, safety, and security in operations. The infrastructure industry transformation must start by addressing the national security and environmental concerns for the hundreds of millions of mission-critical facilities already operating.

Rethinking the onfrastructure industry is aboiuout making the world better, safer and more secure for “We the People” of the whole world.

F. Business case summary.

The infrastructure industry transformation is a national security and environmental imperative and the way to make the world better, cleaner, safer, and more secure for all “We the People” of the world.

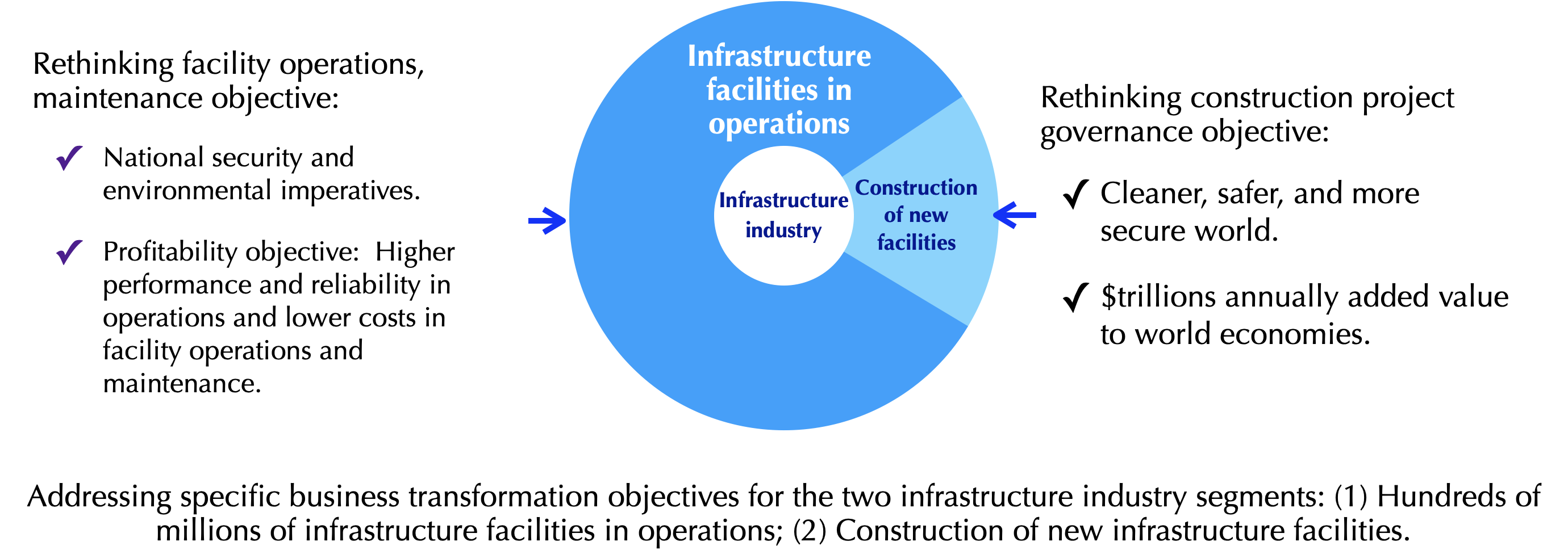

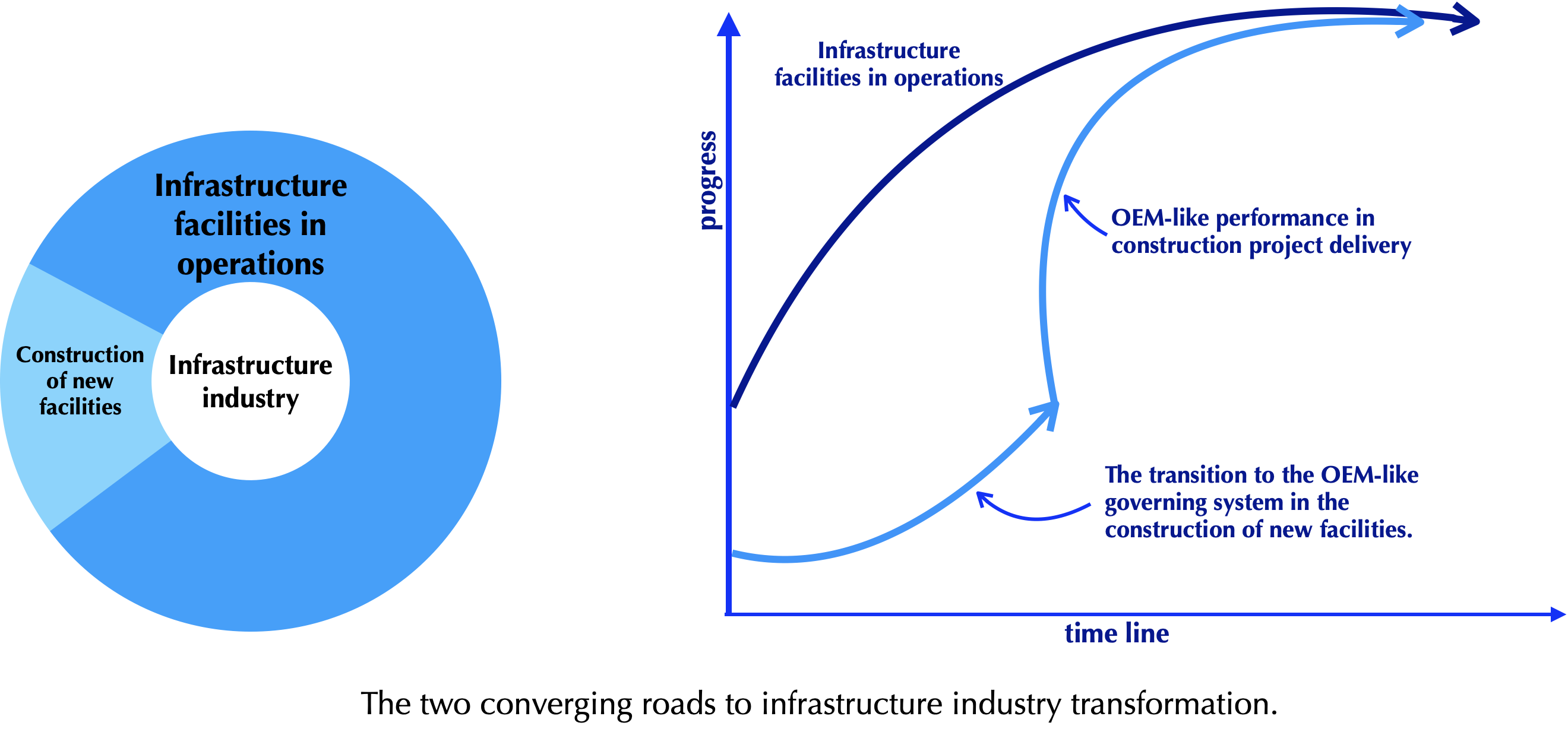

G. Two Converging Roads to Infrastructure Industry Transformation.

The transformation of the infrastructure industry will have to start from its largest segment, the hundreds of millions of critical facilities in operations worldwide, to address national security and environmental imperatives and to enable higher profitability in facility operations and maintenance. More than $100 trillion is the asset value of the operating mission-critical equipment and systems in process and power facilities, a tiny segment of the total asset value of operating infrastructure facilities. Progress in rethinking facility operations and maintenance will create know-how and strong motivation for rethinking project governance in infrastructure facilities.

The top priority is addressing the 21st-level national and environmental objectives in operating hundreds of millions of mission-critical facilities worldwide. Progress in addressing the existing facilities’ national security and environmental objectives will build up the know-how and the motivation for addressing the industry transformation objective in constructing future infrastructure facilities.

The specifics of each one of the two segments of the infrastructure industry call for a specific business transformation strategy and implementation process.

- No changes to the current industry governance system are necessary for addressing the national security and environmental objectives for the existing infrastructure facilities in operations;

- Rethinking the governing of construction projects is impossible unless construction project investors assume an OEM-like role along the whole facility lifecycle and make the facility use value as the governing objective instead of the current minimum construction cost objective.

The above considerations call for two converging infrastructure industry transformation processes: one for addressing the existing facilities in operation and the second for addressing the construction of new facilities. Success in transforming the facility operations and maintenance process will build up the necessary know-how and motivation for transforming governance in the construction of future facilities.

II. Rethinking the infrastructure facility security, operations, and maintenance.

A. IoT-PDT integration is the 21st century product lifecycle digitization standard.

These days, all complex physical products are digitally smart; advanced digital instrumentation and controls and the Internet of Things (IoT) technology enable product operations, remote real-time monitoring, and early detection of equipment and systems pre-failure conditions. The ability to create a product digital twin (PDT) makes the integration of the IoT and PDP digital technologies for the most advanced product operations and maintenance system possible. Infrastructure is the only industry that failed to invest in the Product Digital Twin (PDT) technology.

The IoT-PDT integration is an immense addition to product use value over the years or decades. Infrastructure is the only industry that did not adopt the product digital twin solution; the centuries-old “design drawings and documents” technology continues to be the way to define the facility’s physical and functional configurations. Design drawings and documents do not “talk” with the facility’s digital instrumentation and controls.

The product’s digital twin is the product’s virtual reality that, in many ways, is more powerful than the product’s physical reality in supporting product operations and maintenance processes. The digital twin is not a set of 3D views of the product but a dynamic environment that can produce 3D views, 2D-logical diagrams, in-service inspection procedures, and equipment and systems troubleshooting instructions. The digital product enables simulation of the equipment replacement processing highly congested spaces, simulation of emergency conditions, and the emergency response. The product digital twin enables digital-to-digital communication with the physical product’s digital instrumentation and control to provide context in interpreting alarms.

The IoT technology alone has “Achilles’s weakness”; instrumentation and controls detect abnormal conditions in equipment and process abnormal conditions but cannot tell what causes these conditions. By studying facility drawings and documents, expert process engineers must determine what triggers the signals. A digital-to-digital IoT-PDT integration eliminates this weakness; the facility virtual reality, the product Digital Twin, can tell what the I&C signals mean at the facility system level. The facility’s virtual reality can tell the I&C Loop diagram and the I&C signal source.

B. Product Digital Twin (PDT), and immense transformative power.

The product digital twin is an immense added value along the whole product lifecycle from the project planning phase to product decommissioning. The following set of images are illustration of the basic PDT functionality that enabled revolutionary improvements to facility lifecycle management.

Product Digital Twin. Making posible to build, operate and maintain the infrastructure facility in the virtual space before investing in the making of the physical facility.

Product Digital Twin.

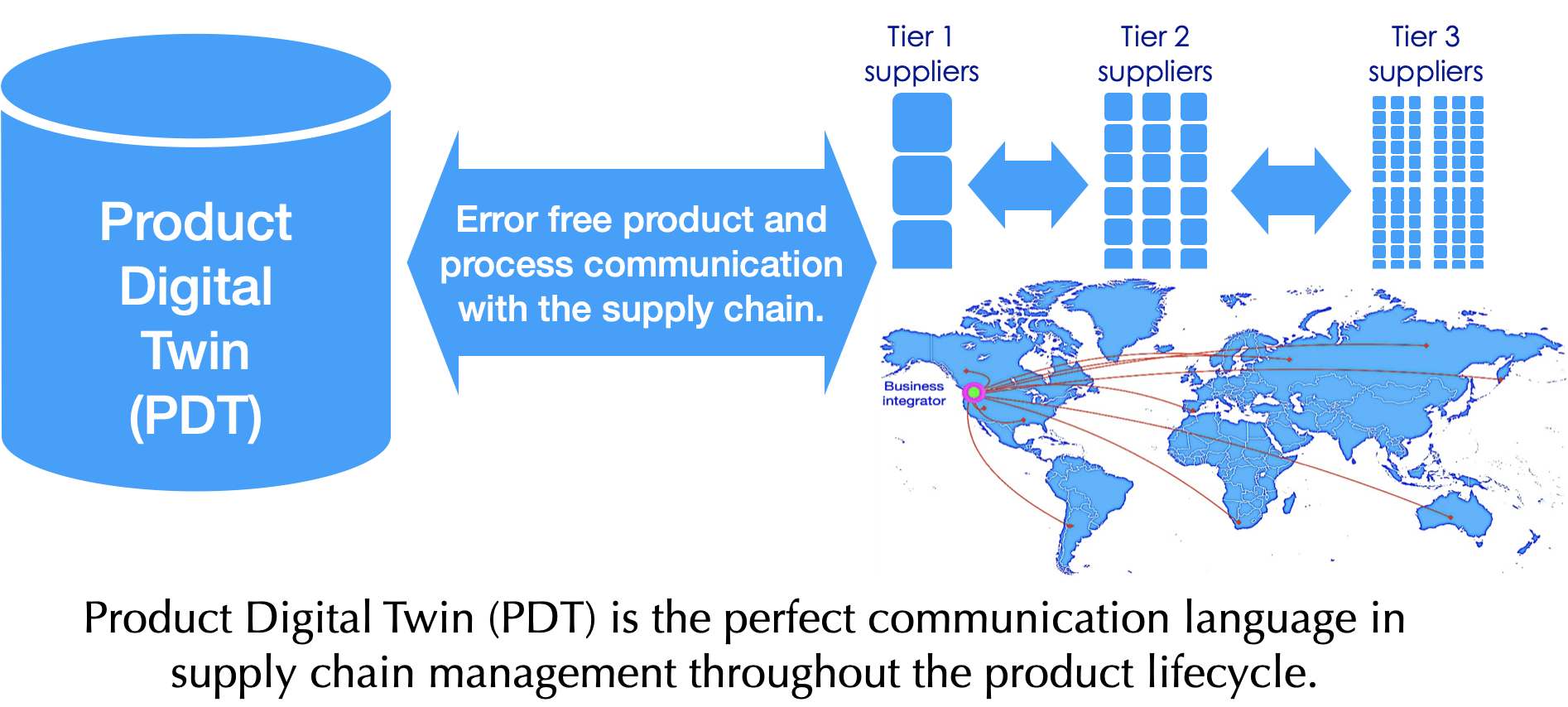

Making posible error free communication with the supply chain.

Product Digital Twin. Making posible digital-to-digital communication in numerically controlled manufacturing.

Product Digital Twin. Making posible digital-to-digital communication with the embedded facility digital instrumentation and controls, the IoT technology.

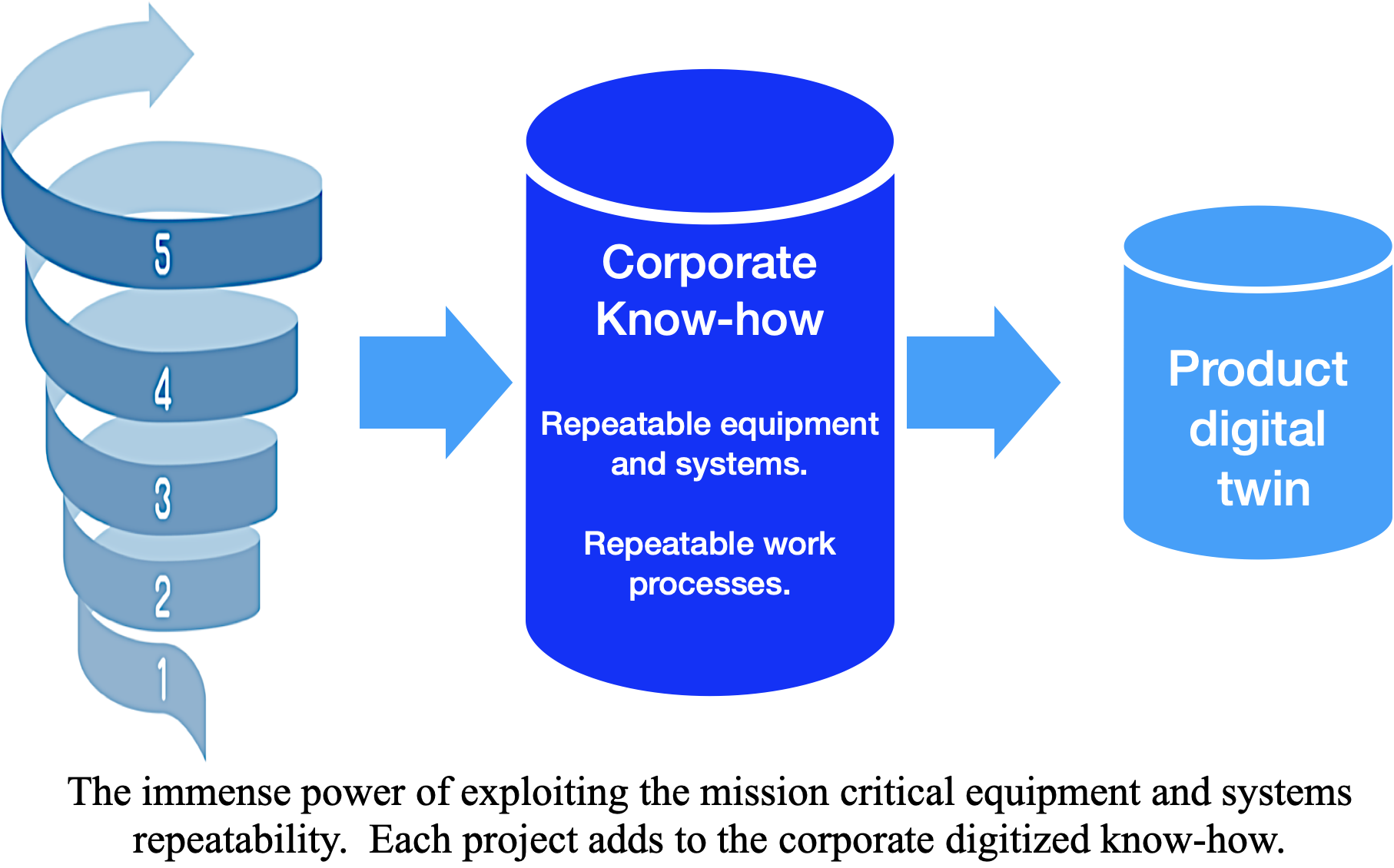

The belief that no repeatability exists in the construction of infrastructure facilities is the consequence of looking the wrong way to repeatability. No repeatability exists at the project level, but a high level of repeatability exists at the components and work processes level.

The “Rethinking Construction” report commissioned by the UK Government determined that more than 80% of components and processes are repeatable.

C. Exploiting the repeatability of the mission-critical systems

to achieve economies of scale in the IoT-PDP integration process.

If done the wrong way, the development of the facility virtual reality, the product digital twin, is complex and costly but easy, fast, and inexpensive when done the right way.

The IOT investment for a complex chemical processing facility is $hundreds of million; the investment for creating a product digital twin is less than $20 million. A complicated chemical processing facility of about $ 1 billion asset value includes more than $ 200 million in digital instrumentation and controls.

Facility mission-critical systems are assemblies of equipment and connecting piping, electrical cables, instrumentation, and controls wiring. The equipment’s very high level of repeatability must be exploited to create re-useable digital know-how in developing the facility digital twin for many facilities. Each new project adds to the corporate know-how, and this is the way to reduce the cost and the duration of the process.

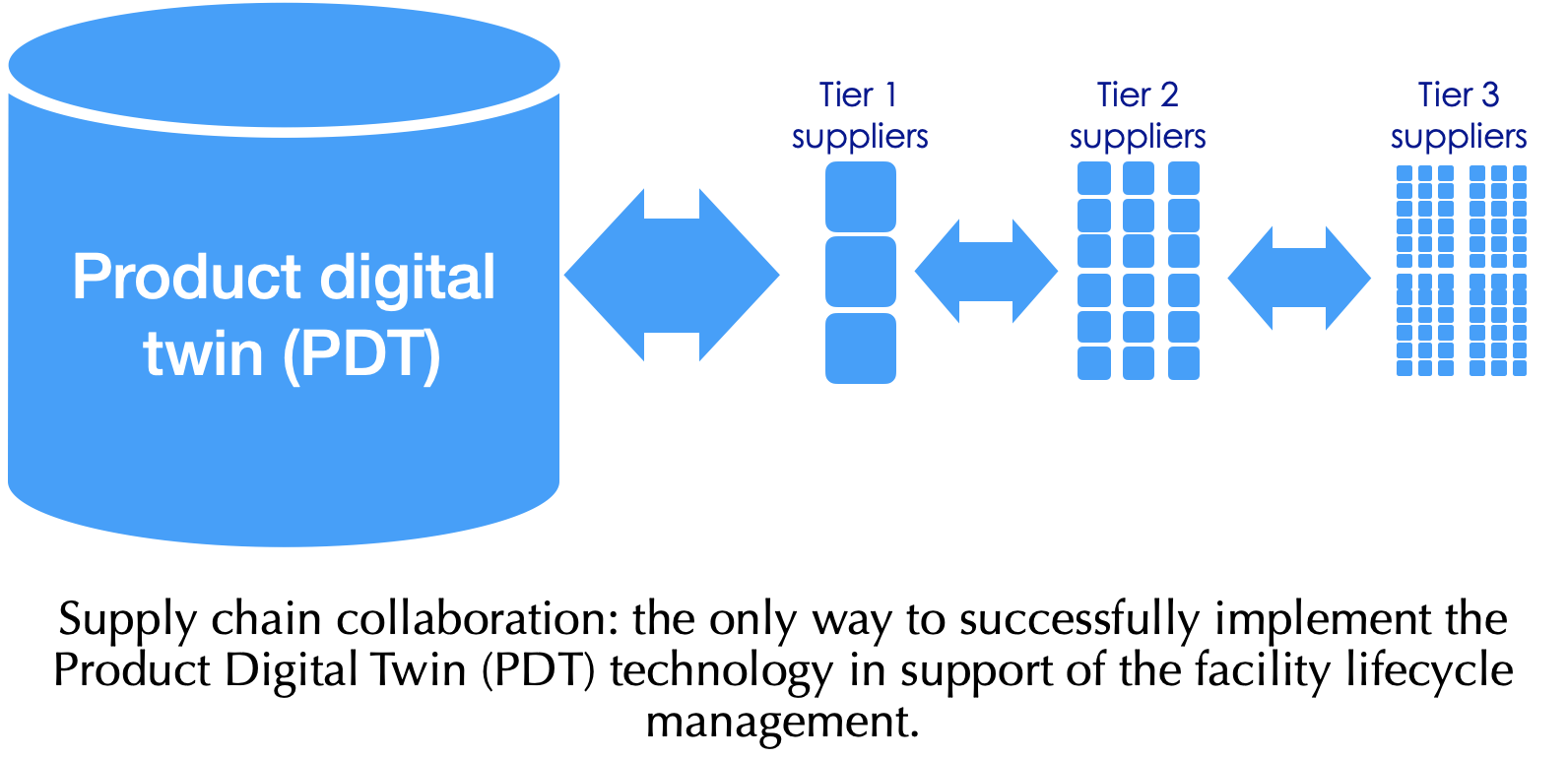

Digitization must be a collaborative process that engages the whole supply chain.

Suppliers that fabricate/manufacture mission-critical equipment and assemble facility mission-critical systems own the equipment and system digital definitions. Collaboration with the supply chain is the way to dramatically reduce the cost and duration of the digitization process for infrastructure facilities in operations.

Construction productivity trend: A puzzling condition.

A highly reliable study indicates that, on average, the whole U.S. economy benefited from about 260% higher productivity, while construction productivity in 2020 was about 40% lower than the 1970 level. During the same period, labor productivity in manufacturing grew nine-fold.

How in the world is this possible when, for over a century, construction has steadily progressed in the off-site manufacturing/fabrication of components, better construction materials, modern construction equipment and tooling, and impressive construction technologies?

III. Anomalies that are symptoms of a project governing system beyond repair:The construction productivity anomaly.

For over a century, construction has steadily progressed in the off-site manufacturing/fabrication of components, better construction materials, modern construction equipment and tooling, and impressive construction technologies. How in the world can this generate decreasing productivity for about fifty years?

A recent study, “The Strange and Awful Path of Productivity in the U.S. Construction Sector,” Austan Goolsbee and Chad Syverson, University of Chicago, Booth School of Business and NBER, January 2023, proves that on average, the whole U.S. economy benefited from about 260% higher productivity, while construction productivity in 2020 was about 40% lower than the 1970 level. During the same period, labor productivity in manufacturing grew nine-fold.

The same study indicates that the decreasing productivity is not limited to the USA.

“To be clear, the raw BEA data suggest that the sector has become less productive over time. A lot less productive: value added per worker in the sector was about 40 percent lower in 2020 than it was in 1970. This downturn did not mirror the economy-wide productivity pattern. Productivity in the entire economy grew throughout the period (albeit with some well-documented accelerations and decelerations). By 2020, while aggregate labor productivity and TFP were 290 percent and 230 percent higher than in 1950, both measures of construction productivity had fallen below their 1950 values. …… While we focus in this paper on U.S. construction sector, the problem of laggard construction productivity growth appears more widespread. In the 29 countries for which the OECD reports construction sector value added per employee growth data over 1996-2019, 16 of the countries—as well as the EU- 27 area as a whole—saw negative average labor productivity growth in their construction.

There is only one way to explain the construction productivity anomaly; the time reported as “construction time” includes significant “no-construction time,” primarily waiting time, the time with no construction progress due to misalignments in scheduling interactions among engineering and construction disciplines. The practice of bidding low to win construction projects leads to the proliferation of low-performance sub-contractors, a condition responsible for significant rework to correct design and construction errors.

The “minimum construction cost” objective does not work!

Most high-complexity national, regional, and city infrastructure projects are delivered years late at excessively higher costs, a condition that troubles most countries, including the highly developed ones.

IV. Anomalies that are symptoms of a project governing system beyond repair:The construction cost anomaly.

The US spends trillions for national, regional, and city infrastructure programs, and $trillions spending should make top-quality construction. It did not happen; the American Society of Civil Engineers (ASCE) did rate America’s infrastructure at level C-, adding that this was “good news” after twenty years of D-level rating.

“For the first time in 20 years, our infrastructure GPA is a C-, up from a D+ in 2017. This is good news and an indication we’re headed in the right direction, but a lot of work remains.“ “A comprehensive assessment of America’s Infrastructure” 2021 Report Card for America’s Infrastructure”, American Society of Civil Engineers.

The Central Artery/Tunnel Project (CA/T Project), commonly known as the Big Dig, a megaproject in Boston, is a convincing example of what can be done given time and money, but far from a good story in program governance. Cost overruns, delays, leaks, design flaws, charges of poor execution and use of substandard materials, criminal charges, and arrests plagued the project. The project was initially scheduled to be completed in 1998 at an estimated cost of $2.8 billion, but it was only finished in December 2007 and cost over $24 billion.

“The Big Dig project exemplifies how it is often governance, rather than scarce financing, that is the main impediment to efficient, effective, and sustainable infrastructure services. Many countries struggle with such governance-related issues, on average wasting about a third of their infrastructure spending due to inefficiencies.” [Infrastructure Governance, March 21, 2022, Ian Hawkesworth Sr Public Sector Specialist, Governance Global Practice, Europe Central Asia Region]

Euronews 02/11/2020 characterized the Berlin Brandenburg Airport Willy Brandt as a disaster in economic terms. It opened in 2020, is ten years behind schedule, and has cost taxpayers around €7 billion — more than three times the estimated sum of €2 billion.

The Denver International Airport project was an ambitious undertaking to build a new airport to replace Denver’s existing Stapleton Airport. The project was launched in 1989 with a budget of $1.7 billion and a commitment to be delivered by October 1993. The project was supposed to create a state-of-the-art airport that could handle the growing number of passengers and airlines using the airport. However, the project faced several challenges that were considered overruns, and schedule delays. The airport cost $4.8 billion, almost three times the original budget, and didn’t open until February 28, 1995, more than a year and a half later than initially planned.

V. Rethinking the Construction Project Governance.

A. The superiority of the OEM governing system.

All complex physical products, including infrastructure facilities, are assemblies of parts fabricated/manufactured by hundreds or thousands of worldwide distributed suppliers.

About 2.3 million parts make a Boeing 787 aircraft. Boeing’s supply channel includes over 6000 tier 1 suppliers based in the 50 American States and more than 100 countries. Ford’s supply channel has about 1200 tier-1 suppliers. About 500 contractors and suppliers collaborate in making a large cruise ship, a giant floating hotel.

Construction projects face a similar supply chain complexity. Bechtel Corporation made known the magnitude of its supply chain management system, which can support successful project deliveries in 120 countries.

“With annual expenditures exceeding $16 billion, we support large, complex projects in remote locations of the world using suppliers from 120 countries. We have the right processes, automation tools, market data, volume, and skilled professionals to meet our commitment to our customers: the responsible purchase and safe delivery of quality goods and services from reliable and diverse suppliers and subcontractors, where they are needed, on time, and at the lowest total cost of ownership. https://www.bechtel.com/services/ procurement.

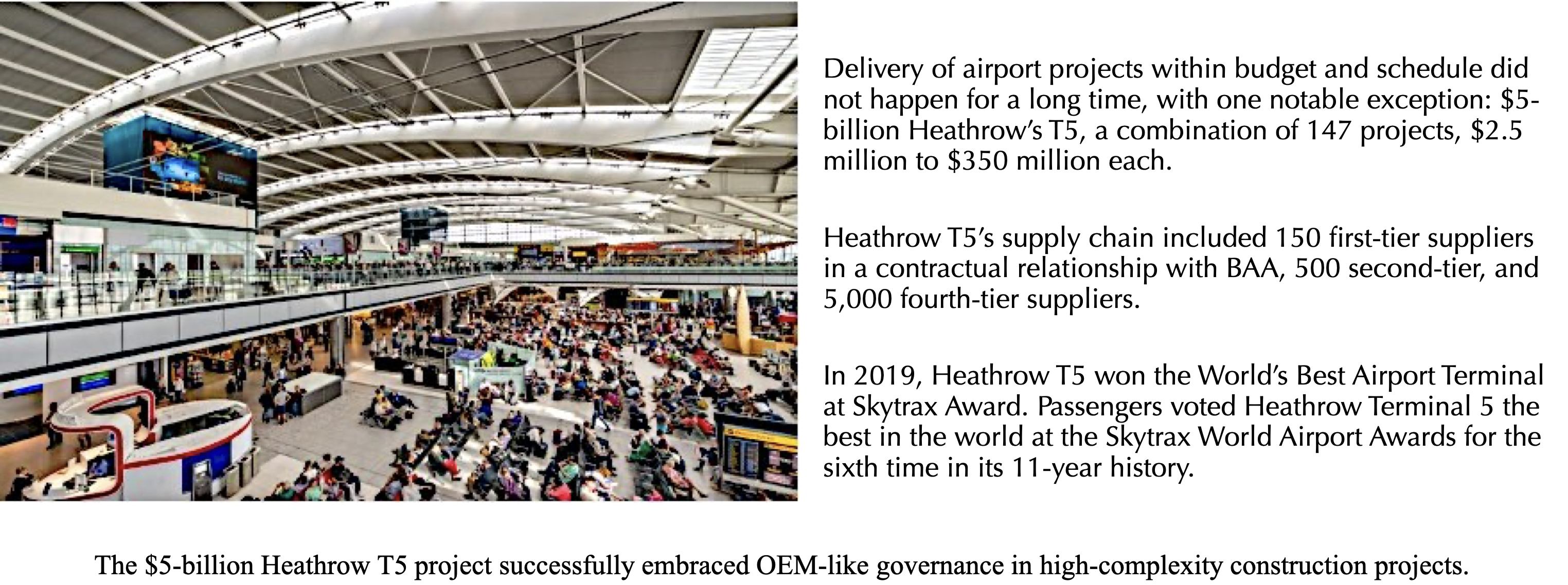

The about $5 billion Heathrow T5 project combined 147 projects, $2.5 million to $350 million each. The Heathrow T5’s supply chain included 150 first-tier suppliers in a contractual relationship with BAA, 500 second-tier, 5,000 fourth-tier, and 15,000 fifth-tier.

The infrastructure industry is alone in taking a different road in the governance of the business of creating new facilities. In manufacturing, the investor organization, the original equipment manufacturer (OEM) organization, perfected what can be named the OEM governance system that serves one clear objective: sustainable profitability by producing competitive product use value. The product use value definition is a very clear one:

- Product performance and reliability in operations;

- Low-cost product operations and maintenance;

- Compliance with the environmental, safety, and security standards.

- The product use value includes artistic, historical, and national values.

To meet this objective, the OEM organization developed long-term partnerships with suppliers of product parts and services, partnerships based on shared business risk and profit. Investments in the integration of two digital technologies, the product digital twin (PDP) and Internet of Things (IoT) are responsible for immense added power to the OEM business success.

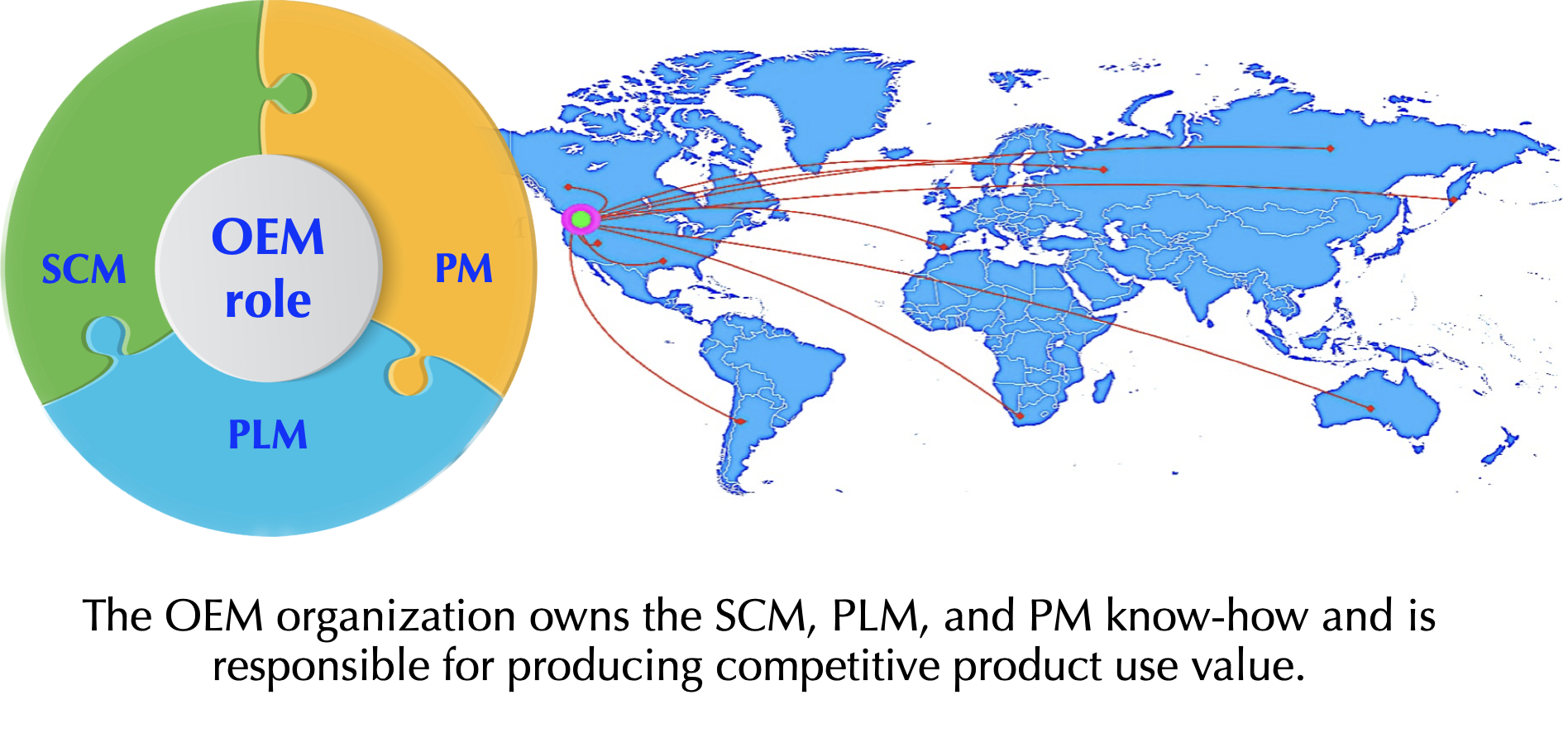

The OEM organization is the keeper of the know-how in product lifecycle management (PLM), supply chain management (SCM), and project management (PM).

In summary, the centerpiece of the business success is the OEM governing role in:

- addressing the product use value as the primary objective in product lifecycle management (PLM);

- supply chain management (SCM) based on long-term partnerships;

- the integration of two digital technologies, PDT and IoT, to support product engineering and manufacturing processes in real-time collaboration with suppliers of product parts and services, and to integrate the product virtual and physical realities in product operations and maintenance

The OEM organization is the keeper of the know-how in product lifecycle management (PLM), supply chain management (SCM), and project management (PM).

B. OEM governance in the delivery of construction projects.

The Heathrow’s T5 success.

The extraordinary success in delivering the $5-billion Heathrow’s T5 terminal proved that investors in construction projects can assume the OEM-governing role in the delivery of complex construction projects. Sir John Egan, Chairman and CEO of the British Airports Authority (BAA), put into practice the “Rethinking Construction” concepts; the revolutionary T5 Agreement was a contractual frame that rewarded performance to motivate the delivery of competitive use value.

“As I chaired the Rethinking Construction government-sponsored think tank, it became clear to me that the role of the client had to be fundamentally different. We needed to think differently about risk management and about long-term relationship with profitable suppliers, who worked with us to change the approach to the computer-based design, design for manufacturing, supply chain management, and safe and efficient processes, thus getting the best out of well-trained workforce.” (Sir John Egan, Foreword to Heathrow’s Terminal 5 History in the Making by Sharon Doherty, John Wiley & Sons, 2008)

According to Sharon Doherty’s “Heathrow’s T5, History in the Making,” the successful making of Terminal 5 is the making of 50,000 people from 20,000 companies and the courage and groundbreaking management thinking in project planning and delivery management. Each of the 50,000 T5 workers was told that T5 was history in the making and that one day, they would be proud to say: “I built Terminal 5.” This is proven true; in 2019, Heathrow T5 won the World’s Best Airport Terminal at Skytrax Award. Passengers voted Heathrow Terminal 5 the best in the world at the Skytrax World Airport Awards for the sixth time in its 11-year history.

Most large investor organizations can develop the necessary OEM know-how and organizational structure. The alternative is to be done in partnership with a construction organization, a long term-partnership based on shared risk and profits.

Adopting an OEM-like governing system is the only way to end decades of $trillions annually lost in world economies.

VI. Why Digital? What Does it Mean?

Digital is part of most of our daily activities. Digital revolutionized communication among organizations and people. It revolutionized the way we order stuff and pay for it. It revolutionized health investigations and monitoring, car driving and maintenance, and airplane flying control.

For most complex physical products, digital has reached the level of integrating the virtual and physical realities of the product along the whole product lifecycle. The physical product is increasingly a digital entity in direct digital-to-digital communication with the product’s virtual “construction.”

Products can now be manufactured/constructed, operated, and maintained in virtual reality before launching any physical product manufacturing. Integrating the two product realities revolutionized the product operations and maintenance processes.

In time, through continuous improvements, the product virtual reality, the product digital twin, will have a higher value than the product physical reality. The digital twin product has the potential to create better and better physical products. The product digital twin will become the way to monetize corporate know-how, the way to win projects, and deliver competitive products.

The infrastructure industry is the only one behind in integrating the physical facility with its digital twin. This level of integration is the responsibility of the investors in the construction of new facilities and the responsibility of the organizations that operate and maintain the existing facilities.

The “digital city” vision of digitally connected infrastructure facilities is now an attainable objective.

VII. Call to Action

Governments, the largest investors in infrastructure facilities, must lead the transformation of the infrastructure industry; they have the highest level of responsibility for the security and performance of the nation’s mission-critical facilities.

Top management consulting organizations can play a significant role in launching the infrastructure industry transformation process; they can significantly benefit from educating governments, corporations, political and public organizations, and regulatory agencies.

“National infrastructure programs are ideal springboards for business transformation.“ “Governments can lead construction into the digital era,” McKinsey & Company, April 10, 2019.

Management consulting organizations to educate governments, political organizations, and regulatory agencies; there are proven ways to end the $trillions annually lost value in world economies and ways to dramatically reduce the high environmental, safety, and security hazards in the constriction process and the operations of industrial and service facilities. The 21st-century governments should stop the immense overspending and the construction of very low-rated national, regional, and city infrastructures.

All schools in engineering and economics are responsible for educating the next generation of engineers and economists to become the necessary force in transforming the largest world industry that builds facilities that make all the other economic sectors and civilized life possible.

Regulatory and public organizations must play a significant role in successfully transforming the infrastructure industry. A higher level of profitability is a powerful incentive, but more is needed; added regulatory pressure helps. The infrastructure industry is the primary source of environmental, safety, and security hazards.

VIII. The author’s credenatials.

Neculai C. Tutos

MS in structural engineering, Ph.D. in computer science. Decades of experience all over the world in the construction of industrial facilities and development of advanced computer–aided engineering solutions.